Product Series

TPX

Overview

TPXTM It has excellent transparency, heat resistance, peeling resistance, etc., and its use is widely involved in industrial materials (including peeling film, peeling paper, high-pressure rubber tube shaft sleeves, LED molds, etc.), food packaging materials (including heat-resistant preservation Films, fresh-keeping bags for fruits and vegetables, etc.), as well as traditional uses such as physical and chemical experimental equipment, microwave oven tableware and so on.

Characteristic

TPXTM It is a specially designed crystalline polyolefin with outstanding heat resistance, easy peelability and transparency.

透明性

甚至在紫外光谱下也具有良好的透光度

易剥离性

低表面张力、仅次于氟化高聚物

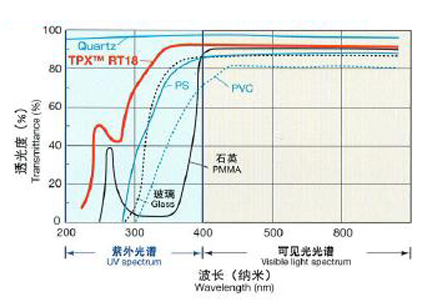

◆ Transparency

TPX is transparent and has excellent light transmittance. In particular, the UV transmittance is higher than that of glass and other transparent resins, so it is also used in optical analysis units.

◆ Heat resistance

The melting point of TPX is 230°C and the Vicat softening point is also high, so it can be used at high temperatures. However, its heat distortion temperature is almost the same as that of polypropylene, so please be careful when considering applications with heavy loads.

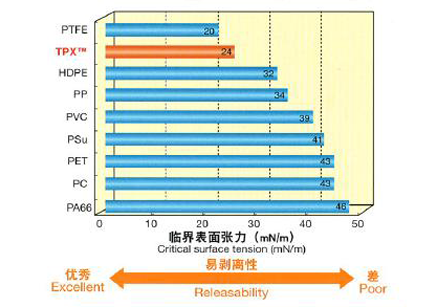

◆ Exfoliation

The surface tension of TPX is (24dyne/cm), which is second only to fluorinated resin, and has excellent peeling properties. This material is used in engineering peeling from other materials (epoxy, polyurethane E). Paper, peelable films for printed circuit boards, and LED molds.

◆ Breathability

TPX resin itself has good air permeability. Using this feature, it is used in the fields of packaging materials for fruits and vegetables and gas separation membranes.

◆ Resistance

TPX is a kind of polyolefin product like polypropylene, so it shows excellent chemical resistance compared with other polycarbonate E and propylene. It is used in various experimental instruments and cosmetic lids.

◆ Steam resistance

Because it is a polyolefin, it is not easy to absorb water, and will not cause performance degradation and size changes due to long-term water degradation. The same is true in boiling water. Using this feature, it can be applied to incubators and iron sinks.

◆ Low density

PX has the lowest density among various thermoplastic resins and has a larger volume than other transparent resins, so it can reduce the weight of molded products. Focusing on its "light" characteristics, it has vigorously developed various products in the leisure field and high-tech products.

◆ Food hygiene characteristics

Our company has brands that comply with various Japanese domestic standard tests (Ministry of Health and Welfare No. 20 and free import product catalogs), US FDA standards. EU food standards, and have a long track record in the field of microwave tableware.

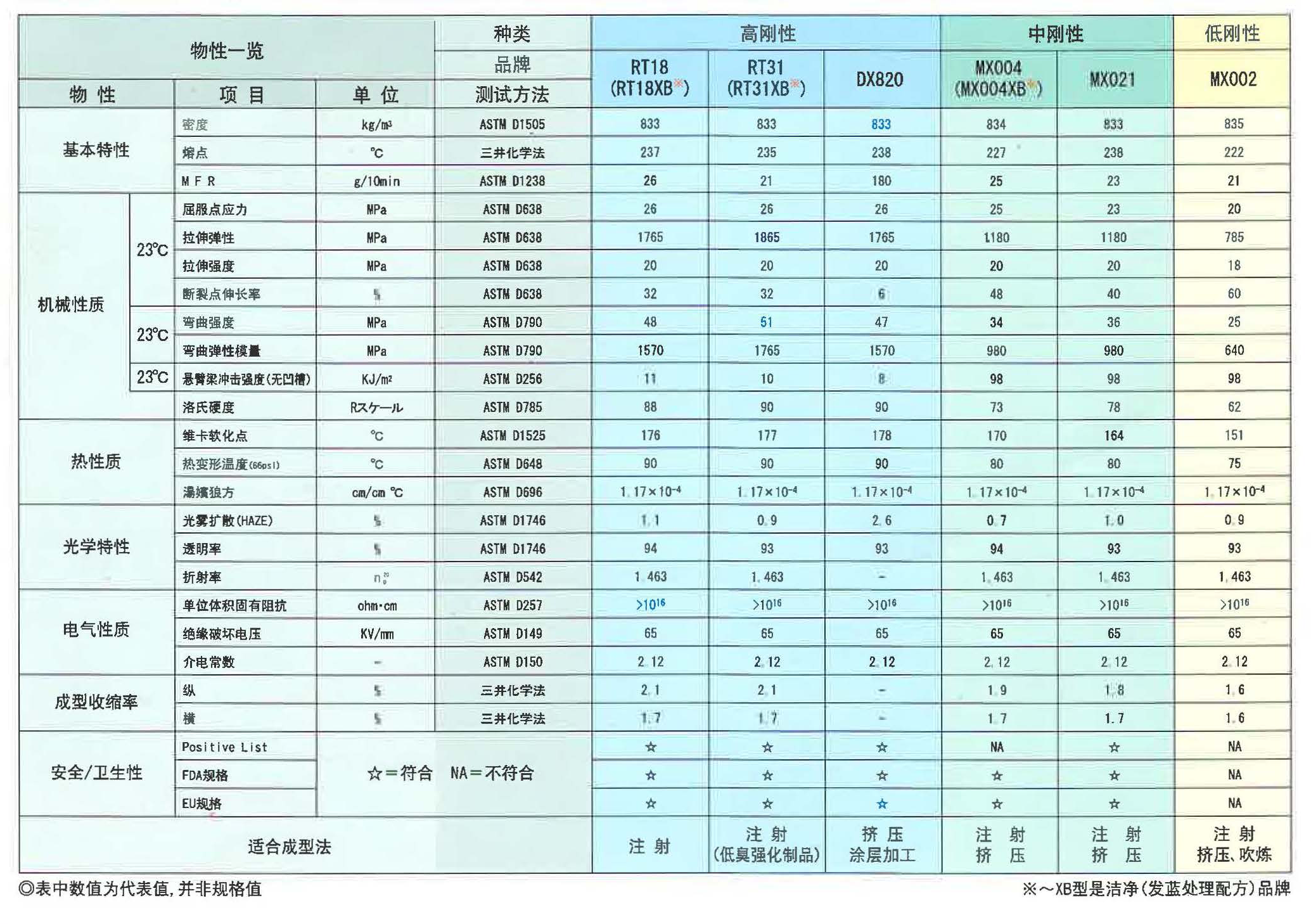

Standard brand properties

Application

○ Rubber hose mandrel

○ Medical and physical chemistry laboratory equipment

○ Food container

○ Packaging material

○ Large spatula

○ electric kettle

○ High frequency connector insulator

○ Microwave tableware and plastic wrap

○ Teapot tea strainer

○ Coffee machine container

○ Steam recovery tank of rice cooker

○ plastic wrap

Partner

Copyright ©2020 Polymer Solutions Limited 粤ICP备2020087627号