Troubleshoot

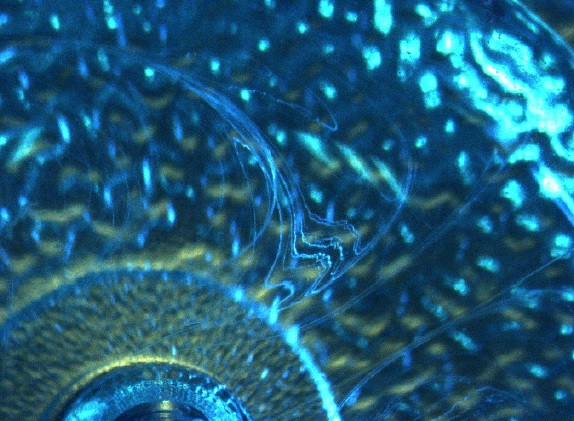

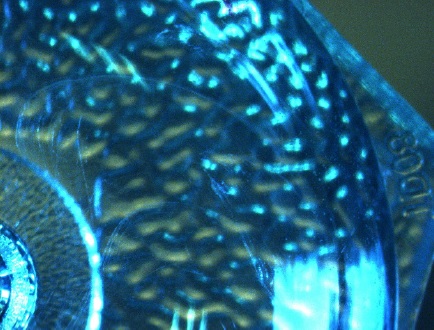

PMMA white dot, bubble, sticky mold solution

PMMA white dot, bubble, sticky mold solution

White bar

Non-pmma plastics were mixed in, and the improvement was as follows

1. Clean the raw materials before opening the package to ensure that the outsourcing is clean

2. Unpack raw materials in a clean environment to avoid excessive dust in the air; Seal the bag immediately after opening it

3. Do not use the outsourcing if it is found to be damaged

4. Raw materials should be stored separately as far as possible, with independent drying conveying system and independent injection molding machine

5. Avoid using plastics after recycling, such as particles released from drying buckets

6. Thoroughly clean the cylinder and surrounding of the injection molding machine

7. Train workshop operators to strengthen their understanding of PMMA operation, especially how to avoid pollution during operation.

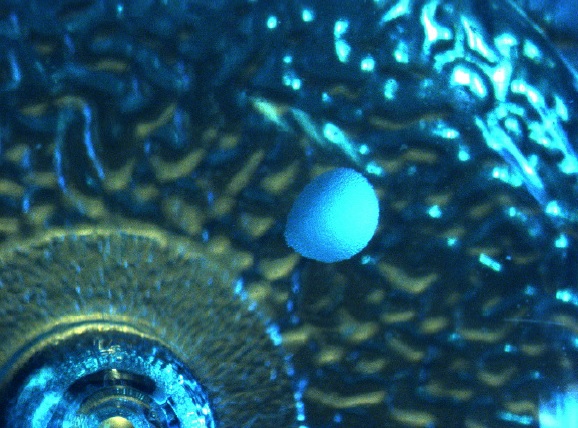

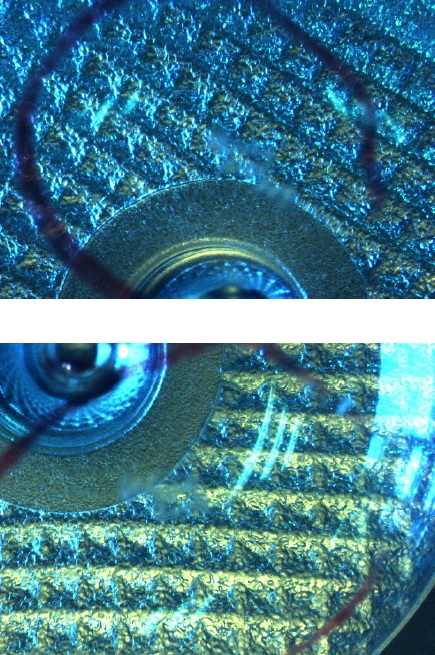

Bubble

Non-vacuum bubbles, caused by gas during injection, improve as follows

1. Before injection molding, ensure that raw materials are fully dry and the water content is less than 0.05%

2. Increase the screw temperature to 235-250 degrees

3. Reduce screw speed and improve back pressure

4. Reduce the injection speed

5. Increase die temperature

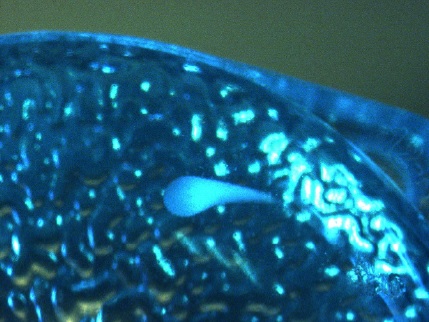

Adhesive die

Mold surface residue caused by cold material, improvement is as follows

1. Reduce mold temperature

2. Lower the temperature of the screw

3. Reduce the retention pressure and time

4. Optimize the setting of graded injection speed

Copyright ©2020 Polymer Solutions Limited 粤ICP备2020087627号